Butterfly valve type introduction and distinction

Release time:

Jun 04,2024

Butterfly valve is a commonly used valve type, with simple structure, small size, light weight, open and close quickly, widely used in various industrial fields. This article will introduce the main types of butterfly valves and their differentiation methods.

Types of 1. butterfly valves

1. Classified by structural form:

• Centrosymmetric butterfly valve: The axial line of the valve stem is at the same position as the central plane of the butterfly plate. The structure is simple and the manufacture is convenient, but the sealing performance is relatively poor.

• Single eccentric butterfly valve: the axial line of the valve stem deviates from the center plane of the butterfly plate, which can reduce the wear of the valve seat and improve the sealing performance.

• Double eccentric butterfly valve: the axial line of the valve stem and the center line of the sealing surface of the butterfly plate are deviated, which has better sealing performance and opening and closing performance.

• Triple eccentric butterfly valve: On the basis of double eccentric butterfly valve, an inclined cone sealing surface is added, which can realize zero leakage. It is one of the best performance butterfly valves at present.

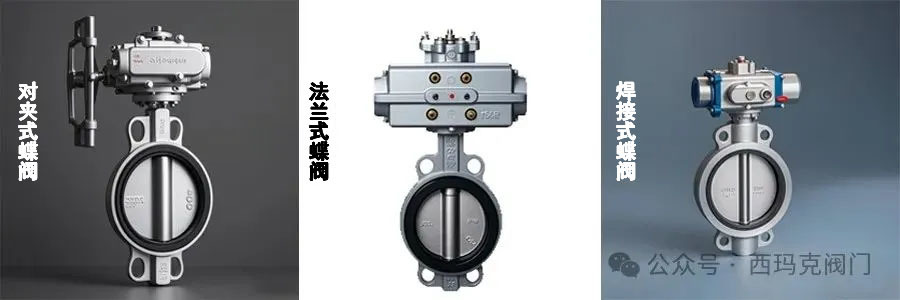

2. Classification by connection:

• Wafer butterfly valve: The valve is clamped between the pipe flanges by bolts, which is easy to install, but difficult to remove.

• Flange butterfly valve: through the flange and pipe connection, easy to remove, but the installation is relatively complex.

• Welded butterfly valve: connected with the pipeline by welding, suitable for high temperature, high pressure and other harsh conditions.

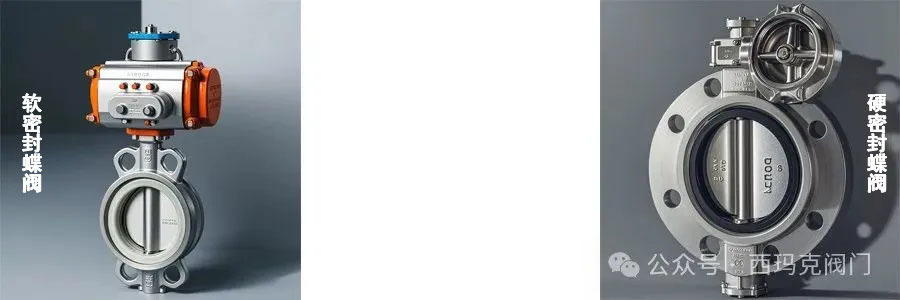

3. Classification by sealing material:

• Soft sealing butterfly valve: rubber, plastic and other soft materials as a seal, sealing performance, but the application of a narrow temperature range.

• Hard seal butterfly valve: the use of metal and other hard materials as a seal, suitable for high temperature, high pressure and other conditions, but the sealing performance is relatively poor.

4. Classification by driving mode:

• Manual butterfly valve: through the handle or worm gear and other mechanisms to manually operate the valve opening and closing.

• Electric butterfly valve: through the motor drive valve opening and closing, can realize remote control and automatic operation.

• Pneumatic butterfly valve: the opening and closing of the valve driven by compressed air, suitable for flammable and explosive and other dangerous places.

Distinguishing method of 2. butterfly valve

1. Structure: By observing the appearance of the butterfly valve, the structure can be preliminarily judged. For example, the stem axis line of the center symmetrical butterfly valve is in the same position as the center plane of the butterfly plate, while the stem axis line of the eccentric butterfly valve deviates from the center plane of the butterfly plate.

2. Connection mode: According to the connection mode of butterfly valve and pipeline, wafer butterfly valve, flange butterfly valve and welded butterfly valve can be distinguished.

3. sealing material: check the butterfly valve seal material, you can determine whether it is a soft seal butterfly valve or hard seal butterfly valve.

4. Drive mode: observe the butterfly valve drive device, you can determine whether it is a manual butterfly valve, electric butterfly valve or pneumatic butterfly valve.

In practical applications, it is necessary to select the appropriate type of butterfly valve according to the specific working conditions and operating conditions. At the same time, attention should also be paid to the material, pressure level, temperature range and other parameters of the butterfly valve to ensure that it can meet actual needs.

I hope this article helps you to understand the type of butterfly valve and how to distinguish it.

If there's anything further you 'd like to know,Simac ValveSincerely welcome to contact us.

Key words:

More news

Why Choosing the Right Bellows Valve Supplier Matters for Your Business

How to Choose the Right Flange Ball Valve for Your Project

Why Choose a Two-Piece Flanged Ball Valve for Your Next Project?

Understanding Cast Steel Floating Ball Valves: A Key Component in Industrial Applications

Butterfly Valve For Wafer Connection Company

Why You Should Partner with a Floating Ball Valve Factory for Exceptional Quality Control

National sales hotline 7*24 hours

Address: 801-805 Jingshan Road, Guannan Industrial Zone, jimei district, Xiamen City