Share:

0. 5 seconds hydraulic control quick shut-off valve

If you are interested in our products, Please contact us

Product classification

Key words:

Product Details

0. 5 seconds hydraulic control quick shut-off valve

SKBYF3H * Y(x)KD743H0. 5 seconds hydraulic control quick closing valve

产品简述/Briefintroduction of products

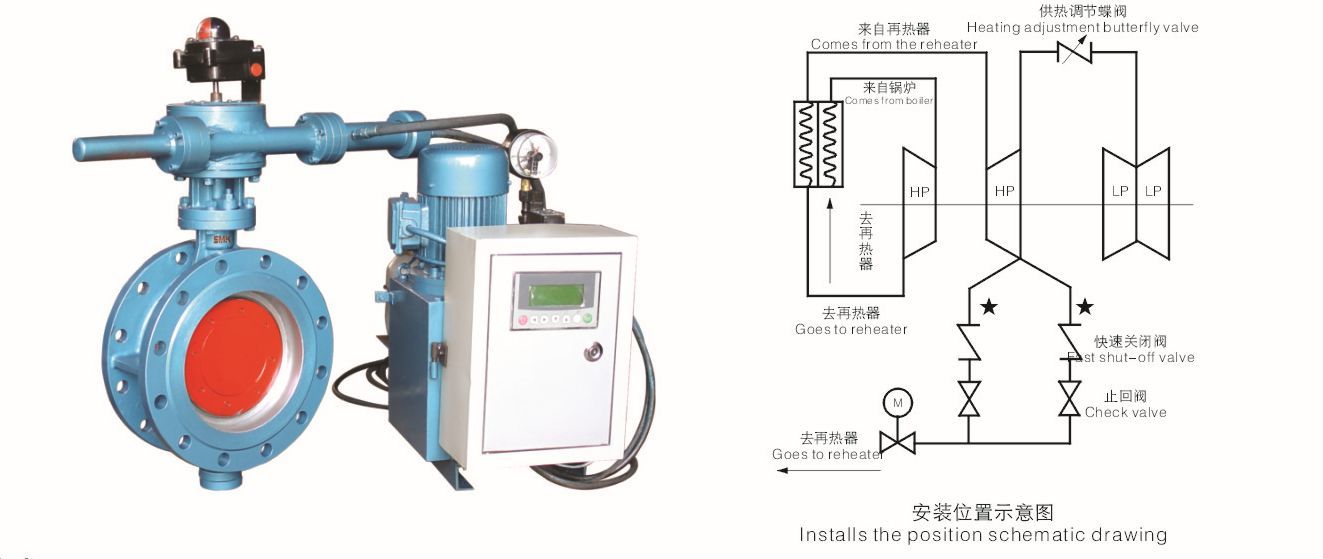

The hydraulic control quick closing valve is mainly installed with high safety level systems such as steam turbine extraction pipeline and blast furnace gas residual pressure power generation device (TRT) intake pipeline, and is used as emergency cut-off valve. In case of crisis condition in the system, emergency valve closing shall be implemented within O. 3~0.8 seconds to realize reliable cut-off of pipeline, effectively prevent steam and condensed water from flowing back or cutting off gas pipeline at the tail of turbine, and protect the safety of turbine unit.

Model Description/Type explaining

Valve Material: C Carbon Steel P Stainless Steel R Chromium Nickel Molybdenum Titanium Steel

Nominal pressure: (Unit: kg/cm2)

Sealing material: H stainless steel W body stainless steel

Structure: three eccentric structure

Connection: flange connection

Drive mode: hydraulic control

Product category: butterfly valve

Functional features: YK spring energy storage quick off, YxK accumulator energy storage quick off

结构及特点/Structure and Characteristics

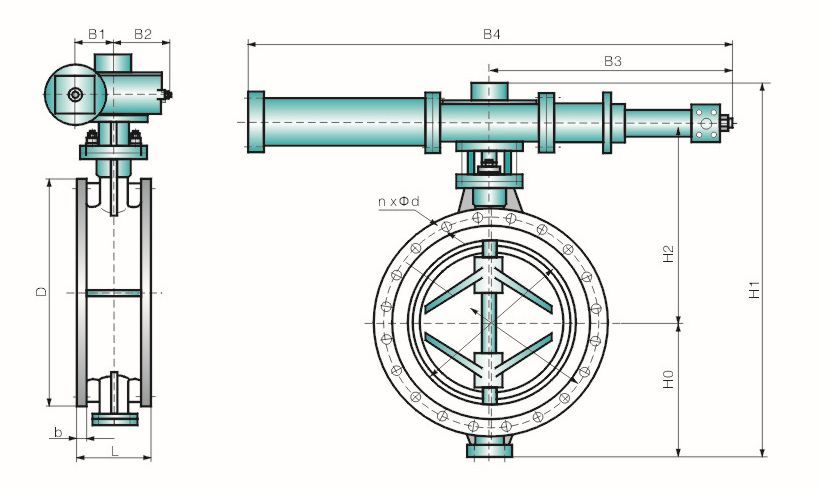

Hydraulic control quick closing valve by the main valve, gear cylinder transmission, hydraulic system, electrical control system of four parts. Each part is highly integrated into a whole, compact structure, greatly saving space.

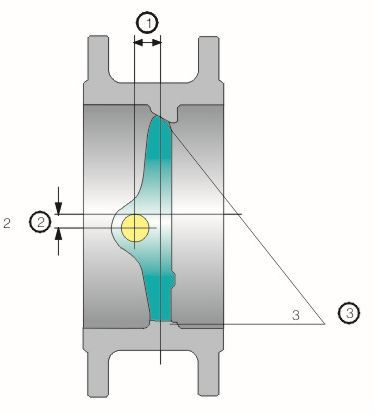

Triple eccentric metal sealing butterfly valve, in the traditional double eccentric structure based on the configuration of the unique angle eccentric design, make full use of the cam effect, so that the valve opening and closing of the sealing pair instantaneous contact, instantaneous separation, eliminating friction and card extrusion, wear small, high temperature resistance, open and close easily, reliable sealing.

The rack and pinion transmission box has a compact structure and is directly connected with the oil cylinder; the tail of the oil cylinder is equipped with a buffer device to eliminate the inertial impact during quick closing and extend the service life of the valve.

According to the different power source, the hydraulic system is divided into two categories: spring energy storage quick closing (YKD) and accumulator energy storage quick closing (YxKD). The normal opening and closing power source of the valve is generally provided by the oil pump unit in the hydraulic system, and can also be derived from the main supporting hydraulic station of the steam turbine. The normal opening and closing speed is controlled by the flow valve adjustment.

The electrical control system is divided into ordinary relay type and PLC intelligent control type according to the main logic component category. The factory matching is generally ordinary relay type, and the PLC intelligent control type should be specified when ordering. In addition to normal open valve, normal close valve, stop, quick close valve and other regular control actions, the system is also provided with a 15% stroke "swimming" function in fully open state to avoid valve jam.

The system is equipped with local control loop and remote linkage control loop. The local control circuit is mainly used for on-site commissioning, and the remote linkage control circuit is generally used during normal work.

The system power supply is AC380V, and the control power supply can be AC220V, DC220V, DC110V or other power supply levels.

For a detailed description of the principle of electro-hydraulic control, please refer to the product installation and operation instructions.

Usage and Maintenance/Uses and maintains

1. When leaving the factory, all parts have been adjusted and set according to user requirements, and generally cannot be adjusted or changed at will.

2, the equipment needs to work under the condition of providing power supply, and requires stable and reliable.

3. As the control valve group of this system adopts many threaded cartridge valves, special attention should be paid to the cleanliness of the oil. It is recommended to bypass the filter oil once every three months.

4. According to the operating conditions, the 24-hour continuous working system must replace the oil every six months, and the high-pressure filter element must be replaced at the same time; the 8-hour intermittent working system can be replaced once after 2400 hours of cumulative use, and the high-pressure filter element can be replaced at the same time. When the system sends out the oil pollution alarm signal, the high-pressure filter element must also be replaced, and the oil cleanliness is not good.

5. Regularly check the liquid level height of the fuel tank. For the first time, it is recommended to add oil to the full level gauge. Under normal working conditions, the oil level shall meet the requirements of above 1/2 height of the level gauge, and oil must be added when it is below 1/3 height.

6. The gas pressure in the accumulator should be checked regularly every month. The normal inflation pressure is 100Bar, and inflation is required when it is lower than 90Bar.

7. After the hydraulic device is put into operation, it is necessary to often go to the work site to observe the operation situation to see if there are any abnormal phenomena such as indication failure and oil leakage. If so, it needs to be handled in time.

8, regular swimming test, in order to prevent the valve jam.

运输与安装/Transportation and installment

1. The transportation requires reliable packaging and dust-proof and rain-proof facilities. The hoisting process should be slow, stable and light to avoid damage to parts due to strong impact and oscillation.

2. If the equipment is not used for a long time, the oil and nitrogen should be released, and the valve should be installed.

3. Install the valve according to the direction of pipeline pressure sealing marked on the valve body.

4, the valve hydraulic device can be integrated with the valve body installation, through the oil cylinder out of the state section directly to the valve body, the requirements of solid and reliable. But there must be support at the bottom of the tank.

5. Open storage of the valve is prohibited.

Note: other pressure, diameter specifications of the valve can be produced according to user requirements.

Note: Other pressures, diameter specification valve may according to the user request production.

Get Quote

Related Products

National sales hotline 7*24 hours

Address: 801-805 Jingshan Road, Guannan Industrial Zone, jimei district, Xiamen City