Share:

Metal hard seal butterfly valve

If you are interested in our products, Please contact us

Product classification

Key words:

Product Details

Metal hard seal butterfly valve

Metal Hard Seal Butterfly Valves

Purpose/Purpose

Simac butterfly valve is suitable for petrochemical industry, power plant, steel plant, industrial food, medicine, environmental protection water treatment and urban construction pipeline for regulating flow and reliable cut off the best fluid device.

This kind of butterfly valve is suitable for foodstuff, pharmacy, petroleum chemical industry, electric plant, steel plant, industrial environmental protection water treatment, and high building, for adjusting flux on water supply tube

Using standard/Adoption standard

Design standards: GB/T12238-1989;JB/T8527-1997;AP1609-2004 can also be specified by the user.

Structure length: GB/T12221-2005;API609-2004

Pressure test: GB/T13927-1992;JB/T9092-1999;AP1598-2004

Design standard :GB/T12238-1989;JB/T8527-1997:AP1609-2004

Structure length :GB/T12221-2005;APl609-2004

Pressure test :GB/T13927-1992;JB/T9092-1999;API598-2004

Electric device/Electric device

Electric device type: partial rotary type, DQW series (made in Yangzhou), HBC/SMC/QB series (made in Tianjin), 802 series/903 series (made in Tianjin North), DQ series (made in Changzhou), etc. Foreign brand image can also be designated by the user.

Power supply voltage: AC380V,AC220V, can also be specified by the user (such as 660V, etc.).

Electromotor actuator type :Partial turning pattern ,such as DQW series(Made in Yangzhou),HBC/SMC/QB series(Made in Tianjin).802 series/903 series(Northern of Tianjin),DQ series of (Made in Changzhou) etc .and it can be specified by user.

Electrical source voltage:AC380V,AC220Vand it can be specified by user(For example,660 V , etc.)

Pneumatic device/Pneumatic device

Pneumatic device type: DA/SR series (Wuxi St. Hans), TAC series (Tianjin Valve Company), etc., can also be designated by the user foreign brand image.

Power supply voltage: AC220V,DC24V.

Appendix: Some parameters of this sample are subject to change without prior notice.

Pneumatic actuator type : DA/SR series (Wuxi St .Hans),TAC series(Tianjin Valve Company),electrical source and

voltage:AC220V,DC24V.

By - laws : This sample some of the parameters to change without notice.

Structure form/Structure

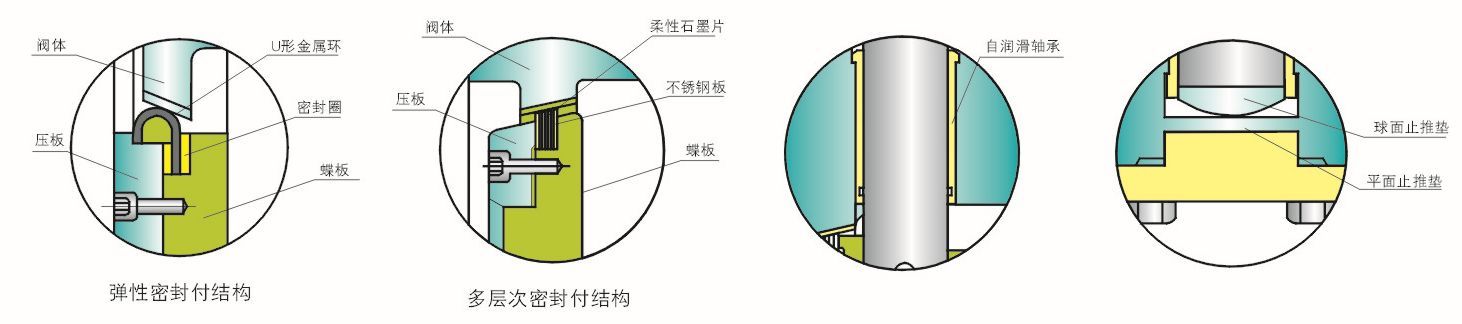

Elastic sealing structure is a metal-to-metal elastic hard seal structure, which is a structural form that will be installed on the valve seat. The U-shaped ring is pressed with a pressure plate and fixed with bolts. Both sides of the U-shaped ring have sealing rings with good sealing performance, high temperature resistance and high pressure, and there is a certain margin. The position of the U-shaped ring can be adjusted to make The valve does not leak due to wear after a period of use. The valve is suitable for medium and high temperature and medium and high pressure piping systems.

Seal flexible structure is a hard flexible metal on metal seal structure will be installed in the valve seat is on a structure .U-shaped ring with clipsand fixed with bolts ,U-ring seals on both sides were very good performance and high temperatures ,high pressure of the ring and have a certain cushion ,you can adjust the location of U-rings ,making valve In the use of the door after a period of time due to wear and do not leak .The application of the valve ,and high- temperature ,high-pressure pipeline system.

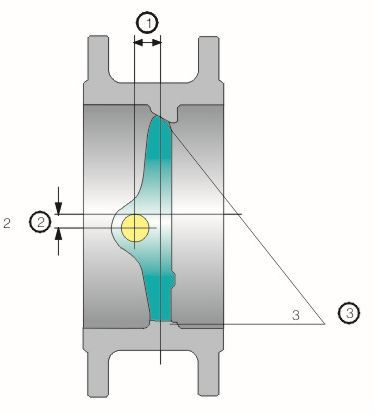

The three eccentric structure is designed to deviate the stem from the center line of the sealing surface to form the first eccentricity; the stem slightly deviates from the center line of the pipeline to form the second eccentricity; the valve plate sealing surface is processed into an oblique section of the cone to form the third eccentricity. Three eccentric structure of the valve seal in the opening and closing process as little as possible to reduce friction, the valve plate began to rotate the moment the sealing surface completely separated, so as to achieve no friction seal. This structure is a qualitative leap of the butterfly valve, so greatly improve the service life of the valve, and the size of the opening and closing torque has been significantly improved.

Three eccentric structure is in the design will stem from the centerline sealing surface ,forming the first eccentric ;stem pipe slightly deviated from the centerline ,a second ecc-entric ;disc sealing surface processed into the cone of a cut-off ramps ,A third eccentric .Three eccentric use of the structure of the valve seal in the course of the hoist as small as possible to reduce friction in the valve plate starting rotation of the moment completely sealed from the surface ,thus achieving a sealed without friction .This structure is a butterfly valve qualitative leap, valves therefore greatly enhance the life, and hoist the size of torque has been noticeably improved.

The key part of the relative movement of the shaft and the body adopts high wear-resistant self-lubricating composite bearings to reduce the friction force of the butterfly plate when it is opened or closed, and to ensure that the shaft and the body are never worn.

Axis and the relative movement of a key part of a high wear-resistant type of self-lubricating bearings ,reducing the butterfly plate in the open or closed when the friction ,ensure that the body axis and never wear.

At the bottom of the lower shaft of the valve body, high hardness and wear-resistant alloy spherical thrust pads and high hardness flat pads are used. During the movement of the butterfly plate, all the downward gravity and friction forces are concentrated here. Due to the high hardness of the two thrust pads, the contact area is small and there is no wear for long-term movement, which ensures that the valve opens and closes easily and never sinks.

Valve in the bottom of the shaft using high hardness wear-resistant alloys spherical thrust pad hardness and high-pad. Butterfly Plate in the campaign process, all have a downward force of gravity and friction are concentrated here. As the two thrust pad hardness, small contact area and wear a long-term campaign to ensure that the valve closed to open easily, never sink

Metal-to-metal multi-level composite hard seal structure is a structural form of multi-level composite seal ring installed on the valve plate. Multi-level composite metal ring is made of stainless steel metal plate and flexible graphite sheet, which has high strength and rigidity. Flexible graphite still has good sealing performance under high temperature and high pressure. The characteristics of these two materials, making the valve suitable for the vast majority of media, the use of a wide range of long service life.

Metal on metal hardware multi-level complex will be sealed structure is a multi-level complex of ring valve installed in a board structure. multi-level complex of metal ring from stainless steel plates and flexible graphite-repeat stack from repression, is of high strength and rigidity; flexible graphite in high-temperature, high pressure is still good sealing perfo-rmance. The balanced characteristics of flexibility and toughness of these two materials, makes the valve and the application of the overwhelming majority of media, the use of a wide range of long life.

Get Quote

Related Products

National sales hotline 7*24 hours

Address: 801-805 Jingshan Road, Guannan Industrial Zone, jimei district, Xiamen City