Share:

Floating structure characteristics

If you are interested in our products, Please contact us

Product classification

Key words:

Product Details

Floating structure characteristics

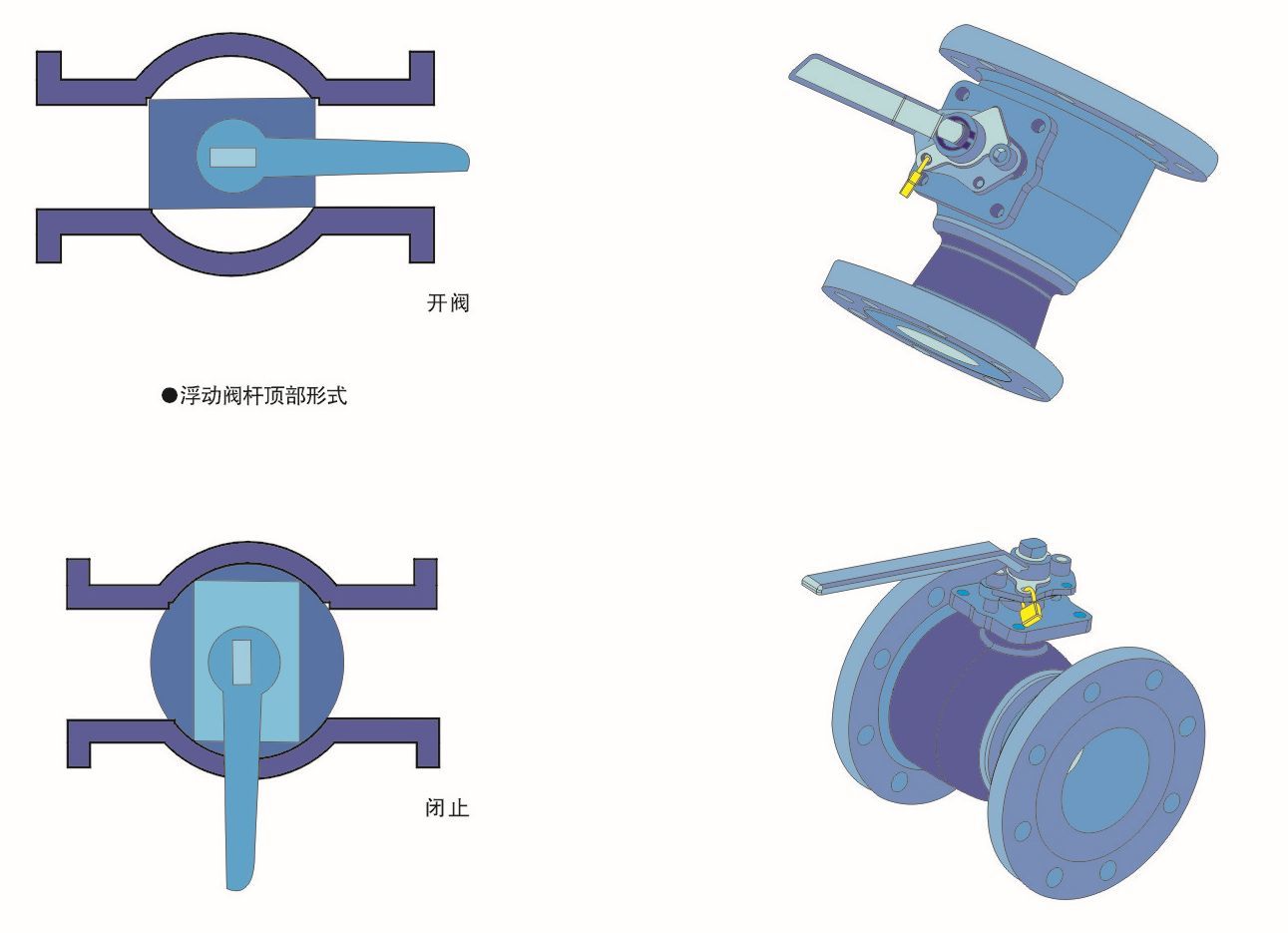

1. Prevent misoperation of the handle

The opening and closing of the valve is often confirmed by the position of the handle. The handle and the pipeline are parallel to the open valve and vertical to the closed valve. However, the connection between the handle and the dry resistance of the ordinary ball valve is flat and square, which is easy to cause misoperation of the valve due to the wrong connection between the handle and the valve stem. The connection between the handle and the stem of the floating ball valve is flat. It is impossible to cause the connection error of the handle, and there will be no misoperation.

2. Locking mechanism

The manual ball valve can be locked with a lock in the fully open and fully closed positions to prevent misoperation of the valve caused by non-workbench personnel pulling the handle. It can also prevent the valve opening or closing and accidents due to pipeline vibration or unmeasured factors. Especially for explosive oil, chemicals and other work pipelines, or field piping occasions, has a more effective role.

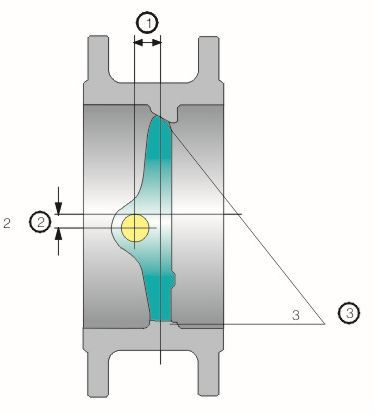

3. Anti-fly-out stem shoulder

Floating ball valve, in order to prevent the risk of the valve stem flying out due to the abnormal increase of the internal pressure of the valve, a shoulder is set at the lower part of the valve stem. In addition, in order to prevent the leakage of the valve stem sealing packing after burning, a thrust bearing is set at the contact between the lower shoulder of the valve stem and the valve body to form an inverted sealing seat to prevent leakage and avoid the expansion of the accident.

For ordinary ball valve, if the valve stem packing burning, or packing gland, bolts have defects, the valve stem by the role of internal pressure easily fly out, fluid overflow, accidents, and even increase the degree of accident, which is not allowed by the safety requirements.

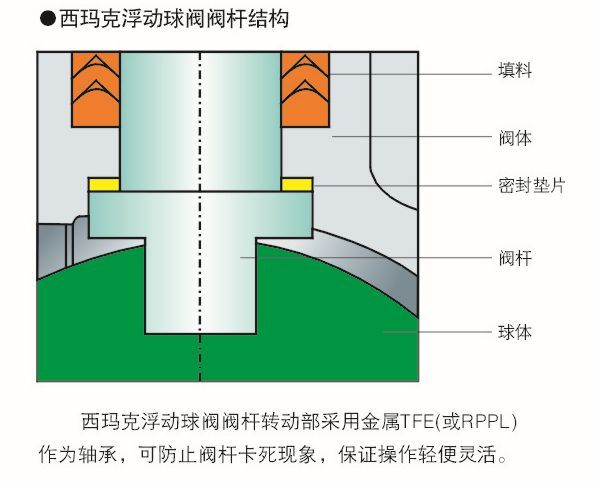

4. Anti-static function

The floating ball valve produced by Simac is to prevent static electricity from being generated due to friction between the ball and valve stem and TFE (or RPPL), which is easy to ignite flammable and explosive media and cause working condition accidents. Between the valve stem and the ball and the ball and the valve body is set up a conductive static spring, so that static electricity through the pipeline into the underground, to ensure the safety of the system.

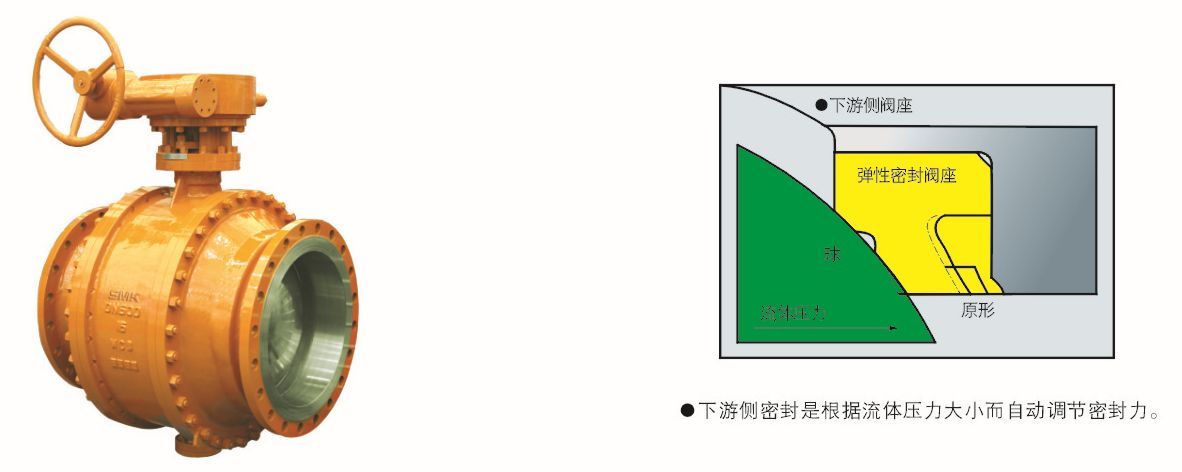

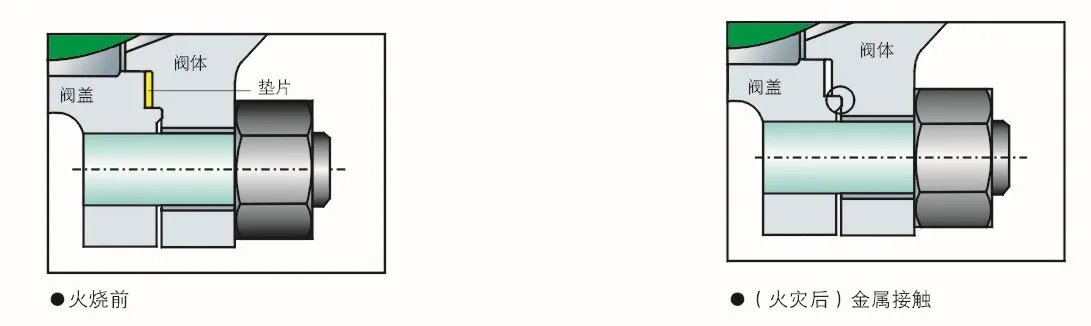

5. Refractory structure

In order to prevent the occurrence of fire or heat accumulation, when the valve seat is burned, a large leakage occurs and the fire is promoted, the stunt ball valve is provided with a fire-proof sealing ring between the ball and the valve seat. When the valve seat is burned, the medium quickly pushes the ball to the metal sealing ring at the downstream end to form metal-metal contact and seal to a certain extent, thus ensuring the safety of the system.

6. Special valve seat structure

Years of manufacturing experience, designed with elastic force of the double seal seat structure, for high pressure, low pressure and vacuum state has excellent sealing effect.

7. No external leakage valve body sealing structure

The joint part of the valve body and the side valve body is sealed by the gasket. Fire, high temperature, vibration, and uneven factors such as opening and torque can cause external leakage there. In addition to relying on gasket sealing, special floating ball valve is specially designed for metal-metal contact between valve body and side valve body to form metal seal and ensure no leakage.

Get Quote

Related Products

National sales hotline 7*24 hours

Address: 801-805 Jingshan Road, Guannan Industrial Zone, jimei district, Xiamen City