Share:

JSQD305 angle stroke adjusting sealing valve

If you are interested in our products, Please contact us

Product classification

Key words:

Product Details

JSQD305

Sealing valve for angular stroke adjustment

Pneumatic Rotary Stroke Regulating Valve

Product overview

JSQD305 pneumatic angle stroke regulating valve (referred to as the regulating butterfly valve) is a rotary control valve, which is used with the valve positioner to achieve the proportion of the valve section. Adjusting screw valve body flow resistance is small, the flow coefficient is large, the valve plate and sealing mechanism has a unique design, both adjustment, cutting new two functions. The regulating butterfly valve is equipped with multi-spring pneumatic diaphragm actuator or pneumatic piston actuator with huge output force and sensitive action, and adopts direct indication and feedback of rotation angle. It is widely used in gas, steam and liquid transportation pipelines in petroleum, chemical industry, papermaking, metallurgy, sewage treatment and other production departments to adjust and cut off the medium flow to achieve the production process according to certain specifications. The F4 and F46 lined butterfly valves are equipped with pneumatic piston actuators, which are especially suitable for the control of corrosive media such as strong acid and alkali in chemical, food and pharmaceutical industries. The rubber lined butterfly valves are especially suitable for the opening and closing or flow regulation of clean pipelines such as food, beverage, medicine and chemical industries, industrial environmental protection, water treatment, nest floor construction, water supply and drainage pipelines.

Standard technical parameters

Valve body

Type: casting butterfly valve (village) valve body

Valve size: DN50 ~ 1000 2 "~ 40"

Rated pressure: PN10, PN16, PN40 ANSI 150 300

Connection form: ANSI GB JB HG JPI JIS DIN

Welding (to be specified by user)

Flange standard: ANSI GB JB HG JPI JIS DIN

Sealing surface type: RF RJ FF RM flange connection

Flange end face distance: as GB12221-89

Material: NCB WC6 WC9 CF3 CF8 CF3M CF8M

Inner parts material: WCB 304 316 304L 316L 17-4PH

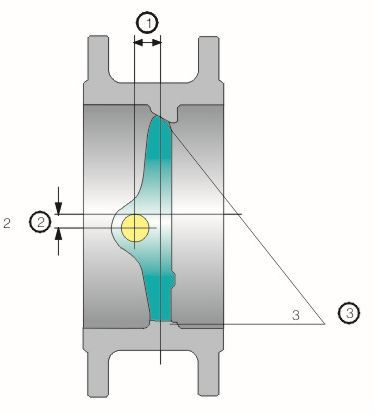

Structure: refer to the drawing

Midline butterfly valve is lined with F4 and F46 and rubber (without eccentricity)

Double eccentric butterfly valve three eccentric butterfly reading

Reinforced PTFE soft seal

(-20 ℃ ~ 180 ℃)

para-polystyrene soft seal

(-60 ℃ ~-300 ℃)

Metal surfacing with steelloy hard seal

(-40 ℃ ~ 450 ℃)

Gap form: pressing plate type

Filler: V-type polytetrafluoroethylene filler, flexible stone filler

Gasket: Form, serrated and flat

Material: F4/discharge F4, stainless steel graphite

Intra-Valve Components

Valve plate: partially spherical, can be lined with F4,F46 or rubber

Approximate Equal Percentage Characteristics (%C)

Sealing drawing: same as valve body (Village F4,F46 or Village glue)

or spherical sealing surface

Material: soft seal reinforced poly (tetrachloroethylene)/para-polystyrene

Hard seal metal surfacing Steele alloy

implementing agency

Form: pneumatic piston actuator (GTX series)

Valve function: single-acting (spring return) air-open and air-closed

Double-acting (double cylinder))

Air supply pressure: 0.4 ~ 0.6Mpa

Angle: 60 °, 90 °

Signal interface: 1/8 "G,NAMUR1/" G

Ambient temperature:-20 ℃ ~ 90 ℃

Valve function

Single-acting (with single-acting actuator)

Air open type, when the air supply fails, the actuator spring closes the valve

Air-off type, when the air supply fails, the actuator spring opens the valve

Double-acting (with double-acting actuator}

Accessories (configured as required)

Positioner, air filter pressure reducing valve, handwheel mechanism, limit switch, solenoid valve, valve position transmitter, continuator, position retaining valve, others

Performance

Rated Kv value: refer to Table 1

Flow characteristics: approximately equal percentage

Adjustable range: 50:1 or 25:1

Seat leakage rate (% for rated Kv):

Metal seal less than 0.01% or 0.001%

(ANSI B16.104-1976IV level)

soft seal

Less than 0.00001%

(ANSIB16.104-1976VI level)

Return difference: less than 1% of full stroke

(with locator)

Less than 3% ~ 5% of full stroke (without positioner)

Basic error: less than 1% of the gold stroke (with positioner)

Less than ± 5% of full travel (without positioner)

Overall dimension: refer to Table 2

Product weight: refer to Table 2

Paint color: the surface of the pneumatic actuator and valve of the regulating valve should be painted, and the valve of stainless steel and copper can not be painted. The arrows and text on the valve body are painted red.

User-specified colors can also be

| Nominal diameter DN(mm) 80 |

Rated flow coefficient Kv 200 |

Piston actuator model GTX75 |

|---|---|---|

| 100 | 405 | GTX110 |

| 125 | 620 | |

| 150 | 1150 | GTX160 |

| 200 | 2030 | |

| 250 | 3150 | GTX210 |

| 300 | 4550 |

| Nominal diameter DN(mm) | Rated flow coefficient Kv | Piston actuator model |

|---|---|---|

| 350 | 6200 | GTX254 |

| 400 | 8100 | |

| 450 | 10260 | GTX255 |

| 500 | 13500 | |

| 600 | 19800 | |

| 700 | 27000 | GTX300 |

| 800 | 35700 |

Note: 1. The list in the table is of standard configuration and can be equipped with different actuators.

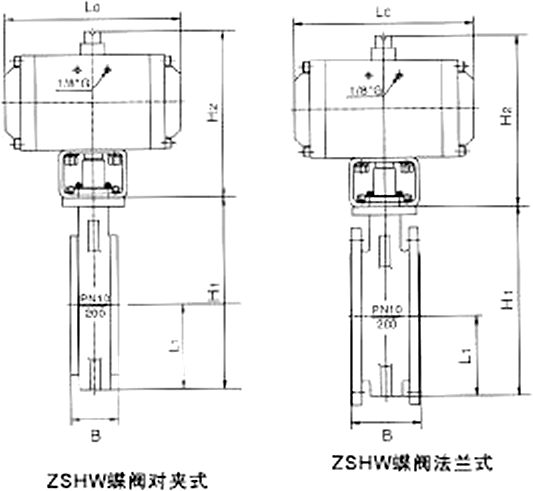

| Nominal diameter DN (mm) | A | L | L1 | L0 | HI | H2 | B | Weight (KG) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| double acting | single action | clip-on | Flanged | |||||||

| 80 | 285 | 330 | 130 | 132 | 203 | 471 | 271 | 49 | 114 | 24 |

| 100 | 285 | 355 | 145 | 222 | 294 | 471 | 271 | 56 | 127 | 29 |

| 125 | 285 | 409 | 175 | 222 | 380 | 497 | 297 | 64 | 140 | 37 |

| 150 | 285 | 427 | 180 | 380 | 380 | 497 | 297 | 70 | 140 | 41 |

| 200 | 360 | 502 | 215 | 380 | 450 | 575 | 375 | 71 | 152 | 52 |

| 250 | 470 | 577 | 250 | 450 | 450 | 693 | 455 | 76 | 165 | 68 |

| 300 | 470 | 641 | 290 | 450 | 603 | 693 | 455 | 83 | 178 | 80 |

| 350 | -- | -- | 305 | 603 | 603 | -- | -- | 92 | 190 | 149 |

| 400 | -- | -- | 340 | 603 | 603 | -- | -- | 102 | 216 | 248 |

| 450 | -- | -- | 380 | 683 | 603 | -- | -- | 114 | 222 | 295 |

| 500 | -- | -- | 410 | 683 | 683 | -- | -- | 127 | 229 | 360 |

| 600 | -- | -- | 480 | 683 | 683 | -- | -- | 154 | 167 | 480 |

| 700 | -- | -- | 535 | 683 | -- | -- | -- | 165 | 292 | 620 |

| 800 | -- | -- | 590 | 683 | -- | -- | -- | 190 | 318 | 750 |

1. The data in the table is PN16 data, the weight data is clip-on type, ZS type is not often attached data, and side-mounted wheels can also be installed for ZM type.

2, ZS type with handwheel mechanism height H4 should be increased by 70(DN80-150),82 (DN200-300),102(DN350-800).

3. The valve body flange and flange end face distance can be manufactured according to user-specified standards, such as ANSI,JIS,DIN and other standards.

Get Quote

Related Products

National sales hotline 7*24 hours

Address: 801-805 Jingshan Road, Guannan Industrial Zone, jimei district, Xiamen City