Share:

Triple eccentric multi-level butterfly valve

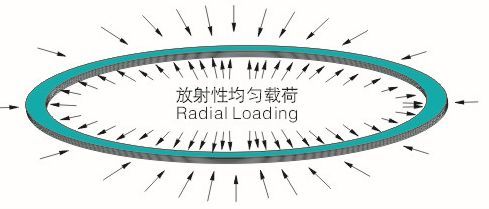

The zero leakage triple eccentric butterfly valve produced by our company relies on the composite stainless steel sealing ring installed on the butterfly plate to achieve real zero leakage. Zero leakage is achieved by the elasticity of the sealing ring on the butterfly plate. The elasticity of the sealing ring (as shown on the right) is produced by its radial compression and flexibility. The contact surface between the sealing ring and the valve seat is an oblique conical surface. The contact angle between the sealing ring and the valve seat produces a slight "wedge effect", which causes the sealing ring to flex and compress radially. Because of the uniform contact between the valve seat and the sealing ring and the flexibility of the sealing ring, the load on the valve seat is uniform, so as to achieve the most tight cut with the minimum torque. The elasticity generated by the torque makes the valve close tightly, regardless of the flow direction of the medium or the force of the medium.

If you are interested in our products, Please contact us

Product classification

Key words:

Product Details

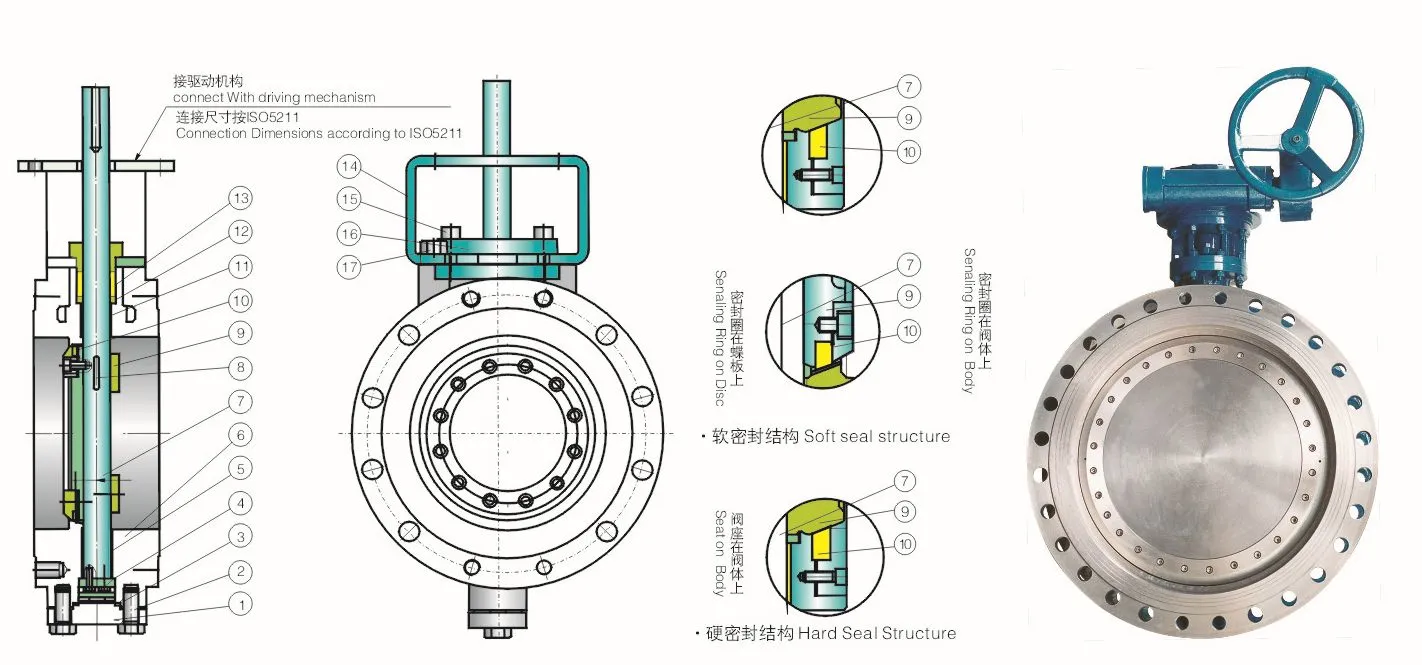

三偏心多层次蝶阀/Three Eccentric Multiple Layers Butterfly Valve

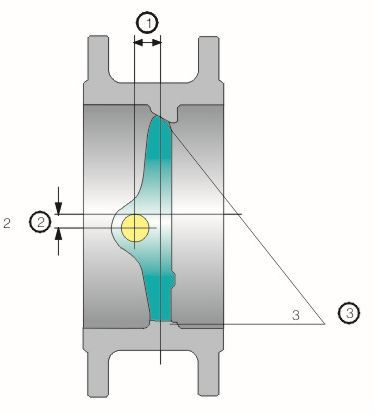

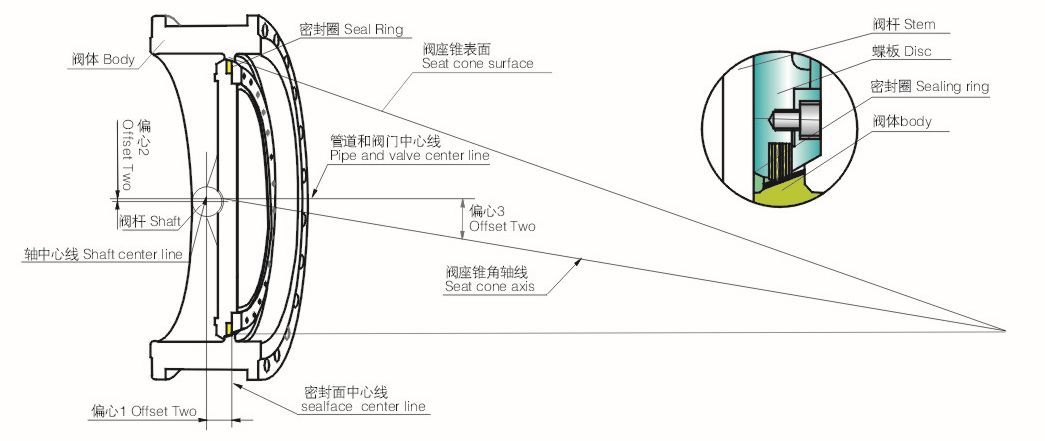

Triple Eccentric Geometry/The triple offset geometry

- Deviation of the first eccentric shaft from the center line of the sealing surface

- The second eccentric shaft eccentric pipeline and valve center line

- Third its unique eccentric valve seat oblique cone angle and the angle of the center of the pipeline, so that the valve seat and the sealing ring in the door throughout the opening and closing process completely separated. This structure uses both the cam effect

Should, and completely eliminate the friction, remove the possibility of wear and leakage. - The first eccentric, shaft deviated from the centerline of sealing face.

- The second eccentric. Shaft deviated from the centerline of pipe and valve.

- The third eccentric, the distinctive included angle between oblique taper angle of eccentric seat and centerline of pipe, thus making the seat completely disengaged from the sealing ring during the whole process of open and close. This structure not only uses cam effect, but also eliminates the possibility of abrasion and leakage.

The zero leakage triple eccentric butterfly valve produced by our company relies on the composite stainless steel sealing ring installed on the butterfly plate to achieve true zero leakage

Our produced the zero leakage three eccentric butterfly valve is implemented by the composite stainless steel sealing ring mounted on the disc.

Zero leakage is achieved by the elasticity of the sealing ring on the butterfly plate. The elasticity of the sealing ring (as shown on the right) is produced by its radial compression and flexibility. The contact surface between the sealing ring and the valve seat is an oblique conical surface. The contact angle between the sealing ring and the valve seat produces a slight "wedge effect", which causes the sealing ring to flex and compress radially. Because of the uniform contact between the valve seat and the sealing ring and the flexibility of the sealing ring, the load on the valve seat is uniform, so as to achieve the most tight cut with the minimum torque. The elasticity generated by the torque makes the valve close tightly, regardless of the flow direction of the medium or the force of the medium.

Zero leakage is implemented by the elastic sealing ring mounted on the disc. The elasticity of sealing ring(see fig. Right) is produced by its radial compression and flexibility. The contact surface between the sealing ring and seat is an oblique cone. The contact angle between them gives slight' wedge effect', making the sealing ring producing flexibility and radial compression. The even contact between the seat and sealing ring, and the closest cutoff by the lowest torque. The elasticity produced by the torque makes the valve closely cut off, regardless of the flow direction or pressure of medium.

特点/Characteristic

- The elastic characteristics of the composite metal seal ring make the valve have zero leakage performance.

- Torque seals ensure continuous bi-directional zero leakage characteristics of the valve.

- The right-angle rotating frictionless design is achieved through a unique triple eccentric principle, which eliminates the friction between the valve seat and the sealing ring during the rotation of the 90 switch.

- STL integrated hard-faced valve seat can meet many working conditions, service life, easy maintenance.

- One-piece cast (plate welded) valve body with structural length conforming to 1SO5752, ASMEB16.10 and AP1609. Can replace high-performance butterfly valves and other types of valves, easy to install, flexible

- All metal structure plus zero leakage performance, so that the valve has the 'nature of fire safety' characteristics.

- The stem anti-blow-out design is safe and reliable, and fully meets the requirements of API609.

- The valve position indicator on the valve stem and the top mounting flange facilitate the butterfly plate position indication.

- Three eccentric butterfly valve stem adopts a through shaft structure, stem and butterfly plate connection using key or pin combination.

- Elastic property of composite metal sealing ring to perform zero leakage

- Torque seal to ensure persistent two-way zero leakage.

- The design of right-angled rotation with zero friction is implemented by the distinctive triple eccentric principle. Lt eliminates the friction between the seat and sealing ring in90 rotation.

- STL one-piece hard-surface seat may adapt to many working conditions, which is featured by long service life and easy maintenance.

- One-piece cast(sheet welded)body, face-to-face dimensions conforming to ISO5752,ASMEB16.10and APl609,replacement to high performance butterfly valves and other types of valves, easy and flexible installation.

- Lntrin sical fireproof property thanks to all metal structure and leak-tight performance

- Anti-blowout stem for high dependability, completely conforming to APl609.

- The valve position indicator on the stem and the flange mounted at the top are in favor of the indication of disc position.

- The stem of triple eccentric butterfly valve is a shaft, stem and disc are connected by of pin-key combination.

flanged butterfly valve/Flange butterfly valve

Get Quote

Related Products

National sales hotline 7*24 hours

Address: 801-805 Jingshan Road, Guannan Industrial Zone, jimei district, Xiamen City