Share:

SOD203 Top Directed Double Seat Regulating Valve

If you are interested in our products, Please contact us

Product classification

Key words:

Product Details

SOD203

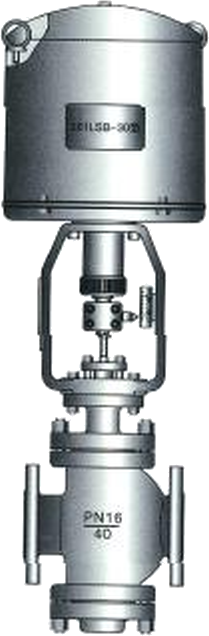

Top-guided double-seat regulating valve

Electric Linear Stroke Regulating Valve

Product overview

SQD203 type electronic two-seat regulating valve adopts cool guiding structure, the valve body structure is tight and light, the fluid channel is S-streamlined, the pressure drop loss is small, the circulation volume is large, the adjustable range is solid and wide, and the flow characteristic precision is high. Since the top and bottom of the valve core guide are fixed and have the characteristics of anti-vibration and wear resistance, the regulating valve is equipped with a small, hard-core and high-precision actuator that receives ON-OFF or 4~20mADC or 1~5V DC signals for proportional action, it is more suitable for good control under the process conditions requiring good dynamic stability, high reliability, high pressure, high pressure difference and easy plugging of slurry in fluid medium.

Standard technical parameters

Valve body

Type: straight through casting ball valve

Valve size: DN20-200mm 3/4 "~ 8"

Pressure Rating: PN16, PN40, PN63, PN100 ANSl 150 300 600 900

Connection form: ANSI GB JB HG JPI JIS DIN

Welding (to be specified by user)

Flange standard: ANSI GB JB HG JPI JIS DIN

Sealing surface type: RF RJ FF RM flange connection

Flange end face distance: as GB12221-89

Material: NCB WC6 WC9 CF3 CF8 CF3M CF8M

Inner parts material: 304 316 304L 316L 17-4PH

Type of gland: pressing plate type

Packing: V-type PTFE packing, flexible graphite packing

Gasket: type, tooth type and peace type

Material: F4/Modified F4, Stainless Steel Graphite

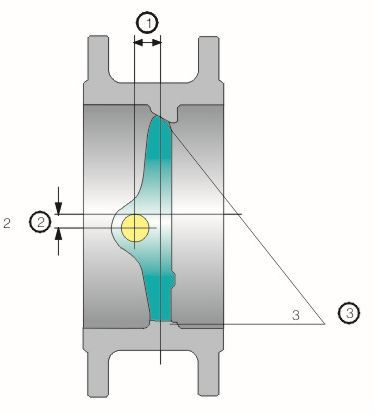

Intra-Valve Components

Structure: pressure balance type

Spool: Double seat plunger type

Metal seal

Equal percentage characteristics (%C)

Linear characteristics (LC)

implementing agency

Type: electric actuator

381lsa/XA1 08, 381lsa/XA1 20,

381LSB/XB-30,381LSB/XB-50,

381LSC-65,381LSC-99,

381LSC-160

Valve role: positive role, reaction

Control action: proportional control or ON-OFF control

Input signal: 4~20mADC or 1 ~ 5VDC input must be selected

Position of the control valve when the signal is "off" (protection, full open, full close)

Power supply: AC220V,50Hz

Output signal: 4-20mADC (load resistance below 5002)

Power Consumption: Type A/50VA, Type B/150VA. Type C/220VA

Protection level: 1P55

Outlet connection: ordinary S type G1/2, explosion-proof X type G3/4

Ambient temperature: no space heater -10 ℃ ~ 60 ℃

With space heater -35 ℃ ~ 60 ℃

Explosion-proof X-type -10 ℃ ~ 40 ℃

Ambient humidity: common S-type actuators below 95%,

Explosion-proof X type 45 ~ 85%

Flameproof grade: ExdIIBT4

over-cutting protection: type a and type B are optional, type c must be matched

Manual device: with handle

Accessories (configured as required)

Space heater, overload protection

Performance

Rated K value: refer to Table 1

Flow thermal: linear, equal percentage

Adjustable range: 50:1

Seat leakage wetness (for the fixed Kv value of the neck%)

Metal seal less than 0.1 percent (ANSI B16.104-1976III)

Less than 0.01%

(ANSI B16.104-1976IV level)

Basic error: ± 1%

Return difference: 1%

Dead band: ≤ 1%

Action time: refer to Table 1

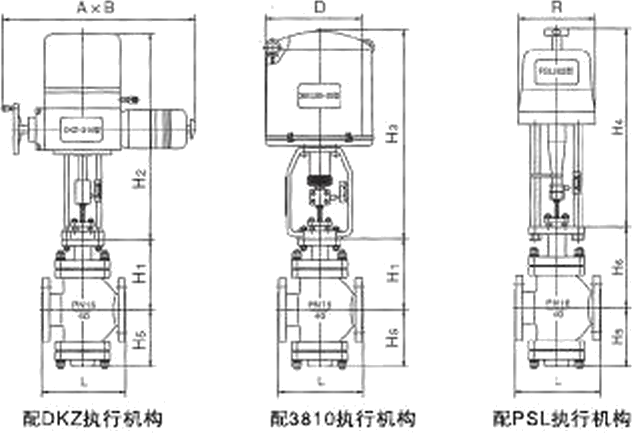

Overall dimension: refer to Table 2

Product weight: refer to Table 2

Terminal diagram: refer to the instruction manual of the equipped actuator.

Oil seepage color: the electric actuator of the control valve and the surface of the valve should be painted, stainless steel and copper valves can not be painted.

The arrows and text on the valve body are painted red.

User-specified colors are also available.

| Nominal through DN(mm) | Seat diameter d(mm) | Rated flow coefficient KV | Motor actuator signal | Output thrust (N) | Rated stroke (mm) | Action time (S) | |

|---|---|---|---|---|---|---|---|

| Linear | equal ratio | ||||||

| 20 | 20 | 6.9 | 6.3 | 381 LSA-08/20 | 800/2000 | 16 | 3.8/7.6 |

| 25 | 25 | 11 | 10 | ||||

| 32 | 32 | 17 | 16 | 381LSB-30/50 | 3000/5000 | 25 | 7.2/14.7 |

| 40 | 40 | 27 | 25 | ||||

| 50 | 50 | 44 | 40 | ||||

| 65 | 65 | 69 | 63 | 381LSB-50/SC-65 | 5000/6500 | 40 | 23.5/14.3 |

| 80 | 80 | 110 | 100 | ||||

| 100 | 100 | 176 | 160 | ||||

| 125 | 125 | 275 | 250 | 381LSC-99/160 | 10000/16000 | 60 | 30/60 |

| 150 | 150 | 440 | 400 | ||||

| 200 | 200 | 690 | 630 | ||||

| Nominal diameter DN | L | A | B | D | R | H1 | H6 | H2 | H3 | H4 | H5 | Weight (kg) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN16/40 | PN63/100 | PN16/40 | PN63/100 | PN16/40 | PN63/100 | PN16/40 | PN63/100 | PN16/40 | PN63/100 | ||||||||

| 20 | 150 | 230 | 460 | 230 | 225 | 177 | 155 | 165 | 171 | 181 | 490 | 373 | 459 | 110 | 140 | 13 | 16 |

| 25 | 160 | 230 | 460 | 230 | 225 | 177 | 155 | 165 | 171 | 181 | 490 | 373 | 459 | 110 | 140 | 16 | 21 |

| 32 | 180 | 260 | 460 | 230 | 225 | 177 | 175 | 180 | 195 | 200 | 490 | 495 | 459 | 130 | 165 | 19 | 24 |

| 40 | 200 | 260 | 460 | 230 | 225 | 177 | 180 | 185 | 200 | 205 | 490 | 495 | 459 | 135 | 170 | 22 | 31 |

| 50 | 230 | 300 | 460 | 230 | 225 | 177 | 200 | 205 | 220 | 225 | 490 | 495 | 459 | 145 | 180 | 23 | 33 |

| 65 | 290 | 340 | 530 | 230 | 225 | 177 | 235 | 245 | 262 | 272 | 540 | 700 | 520 | 175 | 225 | 39 | 49 |

| 80 | 310 | 380 | 530 | 230 | 225 | 177 | 250 | 255 | 277 | 282 | 540 | 700 | 520 | 195 | 245 | 50 | 75 |

| 100 | 350 | 630 | 530 | 230 | 225 | 177 | 260 | 270 | 287 | 297 | 540 | 700 | 520 | 210 | 265 | 59 | 92 |

| 125 | 400 | 500 | 630 | 260 | 310 | 226 | 330 | 335 | 357 | 362 | 625 | 725 | 570 | 265 | 335 | 80 | 129 |

| 150 | 480 | 550 | 630 | 260 | 310 | 226 | 350 | 365 | 377 | 392 | 625 | 725 | 570 | 280 | 360 | 87 | 137 |

| 200 | 600 | 650 | 630 | 260 | 310 | 226 | 420 | 430 | 447 | 457 | 625 | 725 | 570 | 345 | |||

Note:

1. The weight in the table is the data of PSL type actuator.

2. The valve body flange and flange end face distance can be manufactured according to user-specified standards, such as ANSI,JS,DN and other standards.

Get Quote

Related Products

National sales hotline 7*24 hours

Address: 801-805 Jingshan Road, Guannan Industrial Zone, jimei district, Xiamen City